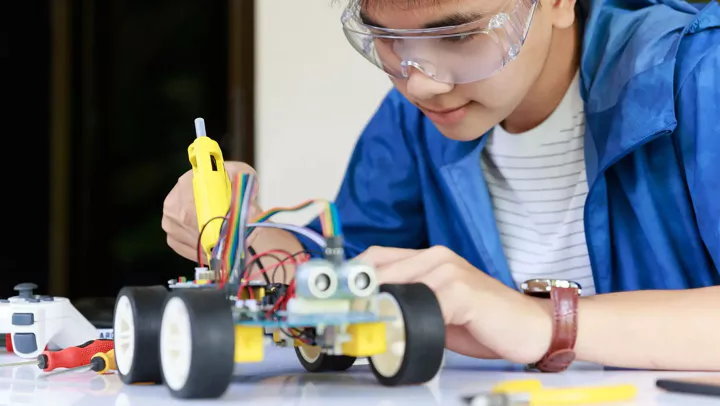

Our programmes have been specially curated to provide your child with the opportunity to explore real-life applications through hands-on mini-projects. Classes are conducted in a fun learning environment with an emphasis on the importance of relevancy. Start your child’s journey in the world of robotics with us today!

Our Programme

Why Us

Our vision is to be Asia’s leading experiential training academy for grooming deep technology talents. We seek to groom young minds in computational thinking and to pick up robotics, automation and coding to future-proof themselves for the new technology age.